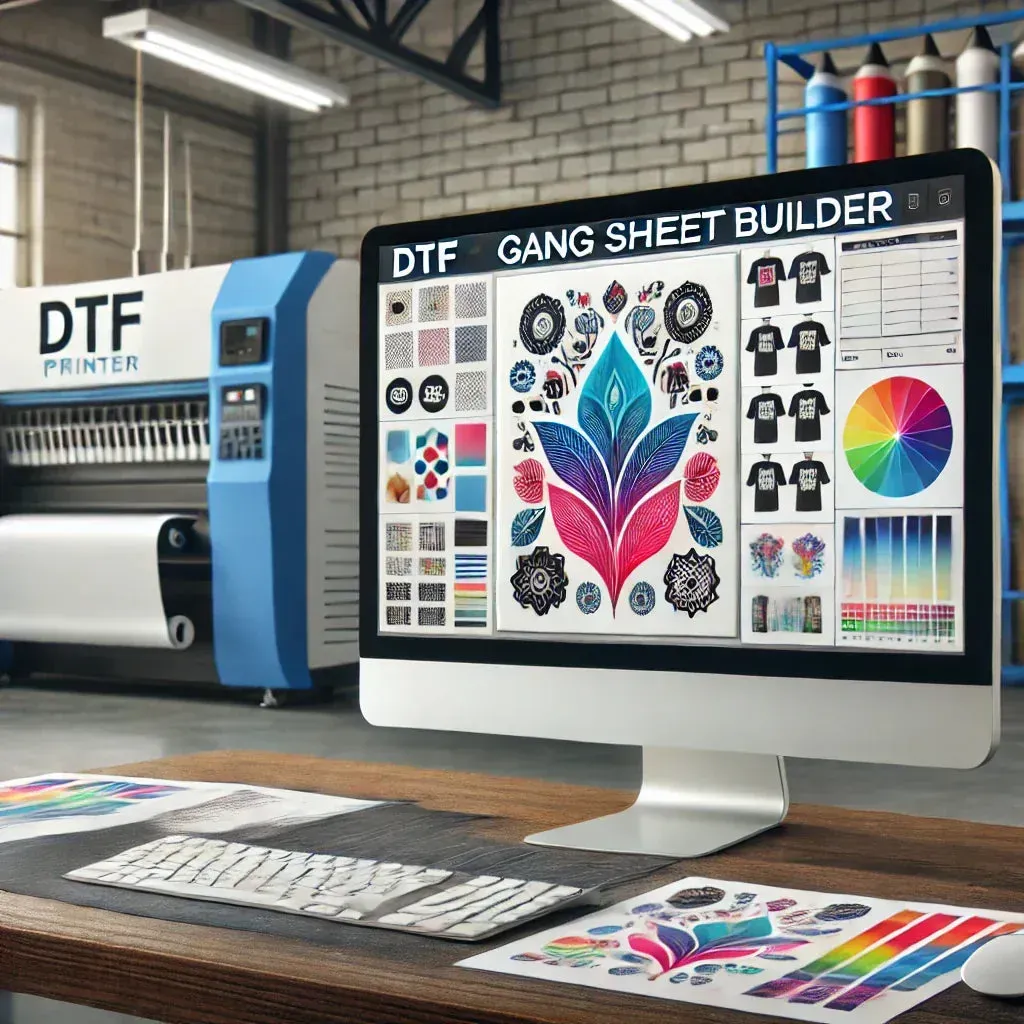

Maximizing efficiency with UV DTF Gangsheet Builder is essential for modern printing businesses aiming to stay competitive and reduce waste. This innovative approach to printing utilizes Direct to Film technology, which not only enhances print quality but also streamlines workflows for better productivity. In today’s fast-paced market, adopting effective strategies such as efficient gangsheet printing can significantly impact your operations, from material usage to turnaround times. As we delve into the intricacies of UV printing management, you’ll discover valuable tips that can elevate your direct to film printing techniques to new heights. By focusing on quality materials, optimized settings, and innovative automation, you can truly transform how your business approaches printing, ensuring not just survival but growth in a challenging landscape.

In the dynamic realm of print production, achieving heightened productivity through strategic processes is a game changer. The concept of gangsheet printing efficiency embodies the idea of optimizing multiple designs in a single print run, thus enhancing overall output and minimizing resource wastage. By incorporating modern direct to film methodologies, businesses can experience revolutionary improvements in their printing workflows. This article will outline various efficient printing strategies tailored to maximize the capabilities of your equipment. Whether you are looking to implement sophisticated color management or refine your staff training, these insights will guide you towards more effective UV printing management.

Understanding the Basics of UV DTF Gangsheet Printing

UV DTF printing allows users to create vibrant, high-resolution prints quickly and efficiently. The gangsheet approach involves printing multiple designs on a single layout, significantly optimizing workflow and reducing material costs. By understanding the fundamentals of this technology, businesses can harness its power to achieve both quality and speed, ultimately leading to higher customer satisfaction. Moreover, knowledge of direct to film printing techniques is essential to maximize output, as it allows for effective planning and execution of jobs.

Integrating efficient printing strategies into daily operations can transform the way a business functions. A detailed understanding of UV printing management leads to smarter resource allocation, minimizing waste and maximizing productivity. As the printing industry evolves, leveraging advancements in technology alongside the fundamental principles of UV DTF gangsheet printing ensures that businesses remain competitive and capable of handling varying customer demands efficiently.

Key Advantages of UV DTF Gangsheet Builder

The key advantage of utilizing a UV DTF gangsheet builder lies in its ability to maximize the use of printing materials without sacrificing quality. This means that businesses can produce a higher quantity of prints in a single run, thereby optimizing time and saving on ink and film costs. By combining multiple graphics into one print run, companies can reduce setup times and maximize throughput, which is a critical factor in a high-demand environment.

Another significant benefit over traditional printing methods is the enhanced versatility of designs. With gangsheet printing, it becomes easier to test various designs without committing to large runs for each. This flexibility encourages creativity and experimentation, allowing businesses to adapt quickly to changing trends and customer preferences. Effectively implementing this strategy can propel a printing business to new levels of efficiency and innovation.

Best Practices for Efficient Workflow Management

To enhance gangsheet printing efficiency, effective workflow management is essential. Employing job queues can streamline the process by organizing print jobs according to complexity and material type, which reduces idle time and setup periods. By optimizing workflows in this manner, printers can maintain a balance between fulfilling large orders while still addressing smaller requests in a timely fashion.

In addition to job organization, continuous monitoring of workflow processes is crucial for identifying bottlenecks. Regular assessments help in implementing changes that promote a more productive environment, enabling quicker responses to unexpected issues. Integrating feedback from staff can also lead to improvements, as those on the front lines often have insights that can further reduce redundancies.

Incorporating Advanced Color Management Techniques

One of the significant challenges in printing is achieving consistent color accuracy across various jobs. Employing advanced color management tools is vital to maintaining quality in UV DTF printing. By creating profiles for different materials and inks, businesses can ensure that colors remain consistent across prints, thus reducing the likelihood of reprints caused by mismatches.

Furthermore, personalizing color settings for specific projects based on prior outcomes can streamline the printing process. Training staff on effective color management techniques can minimize errors and boost overall confidence in executing jobs. This systematic approach not only elevates the quality of outputs but also significantly enhances operational efficiency in the long run.

Harnessing Automation for Enhanced Productivity

Automation has revolutionized many processes in the printing industry, and integrating software solutions into UV DTF printing can yield substantial benefits. By automating repetitive tasks such as file preparation and job setup, print companies can save time and reduce the potential for human error. This allows staff to focus more on intricate tasks, thus enhancing the overall output quality.

Moreover, automated systems can assist in managing queue logistics, ensuring that jobs are processed in a timely manner. This not only keeps the production line moving but also significantly cuts down on the costs associated with delays in the workflow. By embracing automation, printing businesses can streamline operations, reduce turnaround times, and ultimately increase profitability.

Investing in Continuous Staff Training and Development

Continuous training is an imperative aspect of maintaining efficiency in a UV DTF printing business. Investing in regular training sessions ensures that staff are well-versed in the latest technologies and efficient printing strategies. Well-informed employees are more adept at using equipment, troubleshooting issues, and adapting to new techniques, which is crucial in a rapidly evolving industry.

In addition to initial training, fostering a culture of continuous learning can motivate staff to stay up-to-date with industry trends and advancements. Encouraging team members to share insights can lead to collective improvements in processes and techniques. As your staff grows more competent and confident in their skills, the overall productivity and quality of work will undeniably increase.

Frequently Asked Questions

What are the best UV DTF printing tips for maximizing efficiency?

Maximizing efficiency with UV DTF gangsheet builder involves various strategies, such as using high-quality materials, optimizing resolution settings, and implementing effective color management. These aspects help to ensure high-quality prints while reducing waste and reprints, ultimately enhancing productivity in the printing process.

How can I improve gangsheet printing efficiency using UV DTF techniques?

To improve gangsheet printing efficiency, focus on batch printing techniques where multiple designs are printed in a single run. This minimizes setup time and optimizes material usage, leading to significant efficiency gains in your UV DTF printing operations.

What are some efficient printing strategies for UV printing management?

Efficient printing strategies for UV printing management include regular maintenance of equipment, setting up job queues based on complexity, and automating workflows where possible. These practices ensure smoother operations and enhance overall productivity.

How does continuous staff training enhance UV DTF printing efficiency?

Continuous staff training enhances efficiency in UV DTF printing by keeping team members updated on the latest technologies and best practices. Well-trained staff can quickly identify and resolve issues, which helps maintain a smooth production line and maximizes operational efficiency.

What role does software play in maximizing efficiency with UV DTF gangsheet builder?

Software plays a critical role in maximizing efficiency by streamlining workflows and offering tools for design optimization. Utilizing graphic design software with preflight checks can catch errors early, reducing wasted time and resources during the UV DTF printing process.

Why is monitoring outputs important for maximizing efficiency in UV DTF printing?

Monitoring outputs is essential for maximizing efficiency because it allows businesses to track performance and identify recurring issues. This proactive approach enables timely adaptations in processes, fostering a culture of continuous improvement in UV DTF gangsheet printing.

| Tip Number | Tip Description |

|---|---|

| 1 | Utilize high-quality materials for optimal adhesion and durability. |

| 2 | Optimize resolution settings based on graphic complexity to balance quality and speed. |

| 3 | Set up job queues to organize workflows and reduce idle time. |

| 4 | Perform regular maintenance on equipment to prevent breakdowns. |

| 5 | Implement effective color management to ensure consistent outputs. |

| 6 | Embrace batch printing techniques to optimize ink and material usage. |

| 7 | Automate workflows to reduce errors and save time in the printing phases. |

| 8 | Provide ongoing training for staff to keep them updated on new technologies. |

| 9 | Utilize design software to catch issues early in the design process. |

| 10 | Monitor outputs regularly to adapt processes and identify inefficiencies. |

Summary

Maximizing Efficiency with UV DTF Gangsheet Builder is essential for businesses looking to thrive in the competitive printing industry. By focusing on quality materials, optimizing workflows, and investing in continuous staff training, you can significantly enhance productivity and reduce waste. These ten tips provide a structured approach to streamline operations, ensuring that your printing process is not only efficient but also capable of producing high-quality results consistently. By embracing these strategies, companies can adapt to market demands effectively, boost customer satisfaction, and position themselves for sustainable growth.