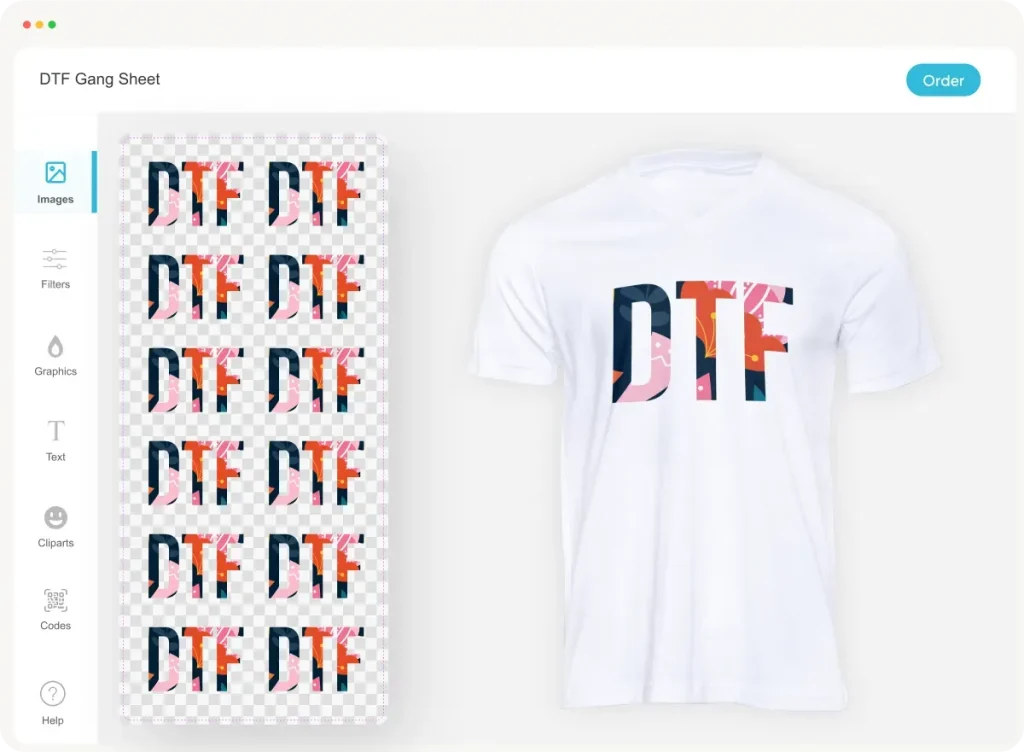

In the dynamic landscape of garment production, the DTF Gangsheet Builder emerges as a game-changer for businesses aiming to enhance their printing efficiency. This innovative software streamlines the Direct to Film (DTF) printing process, offering an effective solution for optimizing gangsheet layout and maximizing material usage. By reducing waste and facilitating cost-effective printing, the DTF Gangsheet Builder significantly uplifts production workflows in print shops. With automated printing features that save time and boost productivity, it’s no wonder that industry professionals are turning to this tool for reliable performance. As we explore the features and benefits of the DTF Gangsheet Builder, you’ll discover how it can elevate your printing operation to new heights.

The world of Direct to Film (DTF) technology is marked by innovations that redefine garment printing. Among them, the Gangsheet Builder stands out for its ability to optimize design layouts on film sheets. This tool ensures that multiple graphics can be printed simultaneously, thus enhancing production efficiency. Additionally, it supports automated processes that significantly reduce manual labor, making it an essential resource for modern printing businesses. As the demand for high-quality and versatile printing solutions grows, technologies like the Gangsheet Builder will continue to shape the future of the industry.

Understanding the Basics of DTF Printing

Direct to Film (DTF) printing has emerged as a game changer in the textile industry due to its ability to print vibrant and durable designs directly onto a special film. This technique allows for high-quality images that can be transferred to various types of fabric, expanding creative possibilities for shirt and apparel makers. Unlike traditional screen printing that often requires extensive setup and can limit creativity, DTF offers flexibility in design and rapid printing capabilities, making it suitable for both small and large production runs.

DTF printing operates by printing the design onto a special film with a specialized ink, which is then treated with adhesive powder. Once heated, the adhesive activates, allowing the design to adhere seamlessly onto garments. This process not only ensures vivid colors but also a soft feel, enhancing the wearability of printed apparel. The scalability of DTF technology allows for tailored solutions for different businesses, whether it’s for custom orders or mass production.

Benefits of Using the DTF Gangsheet Builder

The DTF Gangsheet Builder enhances printing efficiency by optimizing the layout of designs on a single sheet of DTF film. This tool allows users to strategically fit multiple designs on one film, minimizing space wastage and maximizing material usage. Such efficiency translates into significant cost savings, as businesses no longer need to purchase excess films for print jobs. Additionally, the Gangsheet Builder is designed for high-volume production environments, where every second counts in the printing process.

Beyond just cost-effectiveness, the Gangsheet Builder automates tedious manual tasks, allowing print operators to save valuable time. By streamlining the layout process, users can focus on creative aspects and client interactions rather than spending hours calculating the best arrangement for designs. This automation also reduces errors associated with manual placements, ensuring that designs are accurately printed and delivered to customers.

Automated Printing: A Game Changer for Efficiency

The integration of automated printing technology with tools like the DTF Gangsheet Builder marks a new era in garment production. Automation reduces the risks of human error while enhancing production speed, enabling businesses to meet growing customer demands without compromising quality. By leveraging software that controls the printing process, operators can maintain a consistent output, ensuring that each print job meets high standards.

Furthermore, automated printing aligns perfectly with current market trends, where businesses seek to achieve higher efficiency with fewer resources. For instance, while traditional methods often required extensive labor and time, automated solutions streamline these tasks, making it possible to produce larger quantities at a faster rate. This shift not only aids in fulfilling larger orders but also empowers businesses to take on custom projects that were previously unmanageable.

Cost-Effective Printing Solutions with DTF Technology

One of the most compelling advantages of utilizing the DTF Gangsheet Builder is its cost-effective nature. By optimizing film usage and reducing waste, businesses can save considerably on material costs, translating into better profit margins. The ability to fit multiple designs onto a single sheet allows for more prints per fabric used, making it an economically prudent choice compared to other printing methods.

Additionally, cost-effective printing with DTF technology is not just about material savings; it extends to operational efficiencies as well. Businesses that adopt DTF printing will notice reduced overhead costs from lower inventory requirements for films and inks. Ultimately, these financial benefits contribute significantly to overall profitability, allowing businesses to reinvest in further technological advancements or expanded operations.

Design Layout Optimization with Gangsheet Tools

The DTF Gangsheet Builder excels in design layout optimization by providing intuitive tools for arranging graphics seamlessly on film sheets. This feature ensures that designers can experiment with various configurations, determining the most efficient layout without overlap. The ability to visualize the final print before execution helps streamline the production process, fostering creativity while maintaining practicality.

Moreover, this optimization is crucial for businesses looking to maximize output per film sheet. A well-planned gangsheet layout minimizes idle printing time and enhances productivity. By eliminating the guesswork associated with design placement, users can anticipate the quantity of printed materials they can produce in a specified timeframe, ultimately driving better scheduling and resource allocation decisions.

Future Trends in DTF Printing Technology

As the DTF printing industry continues to grow, several future trends are emerging that could further enhance efficiency and quality. Advances in software technology, including the DTF Gangsheet Builder, are expected to include artificial intelligence that aids in layout optimization and design predictions, facilitating even faster production times. Such innovations will empower businesses to maintain a competitive edge in an increasingly crowded market.

Additionally, as manufacturers are integrating printing hardware and software, we can expect more streamlined workflows that reduce the need for manual adjustments. The rise of smart printing technology will also allow for real-time monitoring and adjustments, ensuring that production is consistently high-quality without compromise. These developments signify exciting times ahead for garment businesses embracing DTF printing technology and gangsheet solutions.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve printing efficiency?

The DTF Gangsheet Builder is a specialized software tool designed to optimize the layout of multiple designs on a single Direct to Film (DTF) sheet. By maximizing how designs are placed without overlapping, this tool minimizes material waste and improves overall printing efficiency. Businesses can save costs on film and reduce production time, making it essential for high-volume printing operations.

How does the DTF Gangsheet Builder contribute to cost-effective printing?

The DTF Gangsheet Builder enhances cost-effective printing by allowing users to fit more designs onto a single film sheet. This efficient use of material not only reduces waste but also lowers the overall cost of printing. As a result, businesses can achieve greater profitability by minimizing expenses while maintaining high-quality output.

What features make the DTF Gangsheet Builder essential for garment printing?

Key features of the DTF Gangsheet Builder include layout optimization for efficient design placement, automation tools that streamline the layout process, customization options to fit various garment dimensions, and integrated color management to ensure print accuracy. Together, these features significantly enhance operational efficiency and quality control in garment printing.

Is there a learning curve associated with the DTF Gangsheet Builder software?

While the DTF Gangsheet Builder is designed to be user-friendly, there can be an initial learning curve for new users, particularly those unfamiliar with design software. However, the benefits of increased printing efficiency and automation ultimately outweigh the challenges of learning the system.

How does the DTF Gangsheet Builder aid in maintaining print quality?

The DTF Gangsheet Builder includes advanced integrated color management tools that ensure printed designs closely match digital counterparts. This feature is crucial for maintaining print quality consistency across different productions, which is essential for customer satisfaction in the garment industry.

What recent advancements are related to DTF printing and the Gangsheet Builder?

Recent advancements in DTF printing include the integration of software and hardware, leading to seamless production lines that enhance workflow efficiency. Additionally, the rising adoption of DTF technology by small and medium enterprises is transforming the printing landscape, as these businesses leverage the capabilities of tools like the DTF Gangsheet Builder to improve operational efficiency and competitiveness.

| Key Points | Details |

|---|---|

| Introduction to DTF Printing | DTF printing enhances garment production by using specialized film for high-quality transfers. |

| Benefits of DTF Gangsheet Builder | Reduces waste, saves time, and maintains quality across printed designs. |

| Pros | Cost efficiency, time-saving, better quality control. |

| Cons | Initial learning curve and software costs for small businesses. |

| Key Features | Layout optimization, automation tools, customization options, integrated color management. |

| Recent Developments | Integration of hardware with DTF software and increased SME adoption. |

Summary

DTF Gangsheet Builder is a revolutionary tool for garment printing, allowing businesses to maximize their printing efficiency and reduce waste significantly. By using the Gangsheet Builder, printers can automate tedious layout tasks and maintain high standards of quality, making the production process smoother and more cost-effective. With ongoing advancements in DTF technology, embracing tools like the Gangsheet Builder will not only enhance operational capabilities but also contribute to sustained growth in a competitive market. Essentially, leveraging DTF Gangsheet Builders represents a forward-thinking approach to optimizing printing workflows.