DTF transfer sizes play a crucial role in the effectiveness of Direct-to-Film (DTF) transfer printing, impacting everything from design aesthetics to product functionality. In an industry rapidly embracing customization, understanding how to choose the right size for DTF transfers can set your apparel apart from the competition. Whether you’re looking to create larger, bold graphics or smaller, intricate designs, the importance of DTF transfer size cannot be understated. As businesses continue to explore the latest DTF printing trends, aligning your transfer sizes with best practices will ensure stunning results tailored to your audience’s preferences. By mastering the nuances of custom size DTF transfers, you can enhance the longevity and appeal of your creations, ultimately leading to greater customer satisfaction.

When discussing the dimensions of Direct-to-Film (DTF) transfers, we often refer to these measurements as the size specifications that determine how well a design will fit onto various fabrics. The concept of transfer sizing is essential in ensuring that the artwork aligns perfectly with the intended application area on garments. In fashion and merchandise production, knowing how to gauge the appropriate dimensions can elevate your printing outcomes significantly. One popular alternative term for this process is “DTF transfer dimensions,” which encompasses the careful considerations needed when planning your print layout. As we delve deeper into this topic, understanding the various aspects of sizing will empower you to make informed decisions in your apparel projects.

Understanding DTF Transfer Sizes

When considering DTF transfers, the size of the transfer is a pivotal element in the success of any project. DTF transfer sizes must be carefully evaluated to match the dimensions of the design space on the garment. Incorrect sizing can not only detract from the aesthetic quality but also diminish the garment’s wearability. Ensuring that the transfer effectively occupies the designated area can significantly enhance visual appeal, making it more captivating to potential customers.

Moreover, the proper sizing of DTF transfers can help in maintaining the integrity of the fabric during the application process. A transfer that is too large may lead to issues such as bubbling or distortion, where the design fails to adhere properly. This not only ruins the final look of the product but can also affect its durability. Thus, understanding and selecting the appropriate DTF transfer size is paramount for achieving a harmonious blend of design and function.

The Role of Custom Size DTF Transfers

In today’s market, customized solutions are increasingly sought after, as consumers desire products that resonate with their personal styles and preferences. Custom size DTF transfers allow businesses to deliver unique designs tailored specifically for their clients, ensuring a personalized touch that sets them apart from competitors. By accommodating specific requests for size, businesses can cater to a broader audience ranging from oversized sports apparel to more subtle and intricate fashion pieces.

Additionally, the shift towards custom size DTF transfers is indicative of broader trends in the fashion and merchandising industries. As producers gain access to advanced printing technologies, the ability to offer bespoke transfers becomes more feasible. This adaptability not only boosts customer satisfaction but also enhances operational efficiency, as companies can optimize their print runs based on actual size requirements, reducing wastage and improving overall profitability.

Best Practices for Optimizing DTF Transfer Sizes

To achieve the best outcomes with DTF transfers, applying best practices in sizing is essential. One effective approach is to work closely with your print providers to create a sample transfer prior to bulk production. This collaboration ensures that the dimensions are perfectly aligned with both the design and garment specifications. Neglecting this step can lead to costly mistakes and unhappy customers.

Testing various sizes before making a final decision can also vastly improve the quality of the finished product. Experiments can reveal how size affects placement, detail visibility, and overall appeal on the garment. By having a range of options at hand, designers can make informed decisions that best reflect their clients’ wishes and the garment’s characteristics, ultimately achieving that perfect fit.

Trends Shaping DTF Transfer Sizing in 2025

As we progress into 2025, DTF transfer sizing is being influenced by several emerging trends. One significant trend is the increasing demand for sustainable practices, where businesses strive to minimize waste by producing transfers that are as close to ideal size as possible. This effort not only reduces material waste but also aligns with customers’ growing preference for brands that prioritize eco-friendly production methods.

Additionally, technological advancements in DTF printing are setting the stage for more precise sizing options. As the technology improves, producers can easily adjust sizes without compromising quality. This means that in the future, businesses will not only be able to provide custom size DTF transfers efficiently but also refine their offerings in line with customer preferences quickly and effectively.

Importance of Collaboration in DTF Printing

Collaboration plays a crucial role in the successful application of DTF transfers, especially regarding sizing. Close communication with print providers can aid in illuminating potential issues before they arise, ensuring that transfer sizes meet the requirements of both the design aspect and the characteristics of the fabric being used. By fostering a cooperative relationship, businesses can streamline their production processes, enhancing quality control and customer satisfaction.

Furthermore, feedback from clients should also be integrated into this relationship. Understanding the end consumers’ perspectives can provide valuable insights into preferred sizes, which can influence printing practices. Continuous dialogue not only helps to mitigate sizing discrepancies but also lays the foundation for innovation in transfer design and production, leading to better results and higher sales.

Future Considerations for DTF Transfer Sizing

Looking ahead, the future of DTF transfer sizing appears to be one of adaptability and technological integration. Businesses that remain attuned to changing consumer preferences and advancements in printing technology will be at a significant advantage. As personalization in apparel continues to rise, the ability to customize transfer sizes rapidly will likely become a critical competitive differentiator.

Moreover, staying informed on the latest DTF printing trends will enable businesses to refine their strategies continually. As new materials and techniques emerge, companies that embrace these innovations will enhance their offerings and maintain relevance in a fast-evolving market. The emphasis on size will not only link to performance but also to overall customer experience, solidifying the role of DTF transfers in modern fashion.

Frequently Asked Questions

What are the different DTF transfer sizes available for printing?

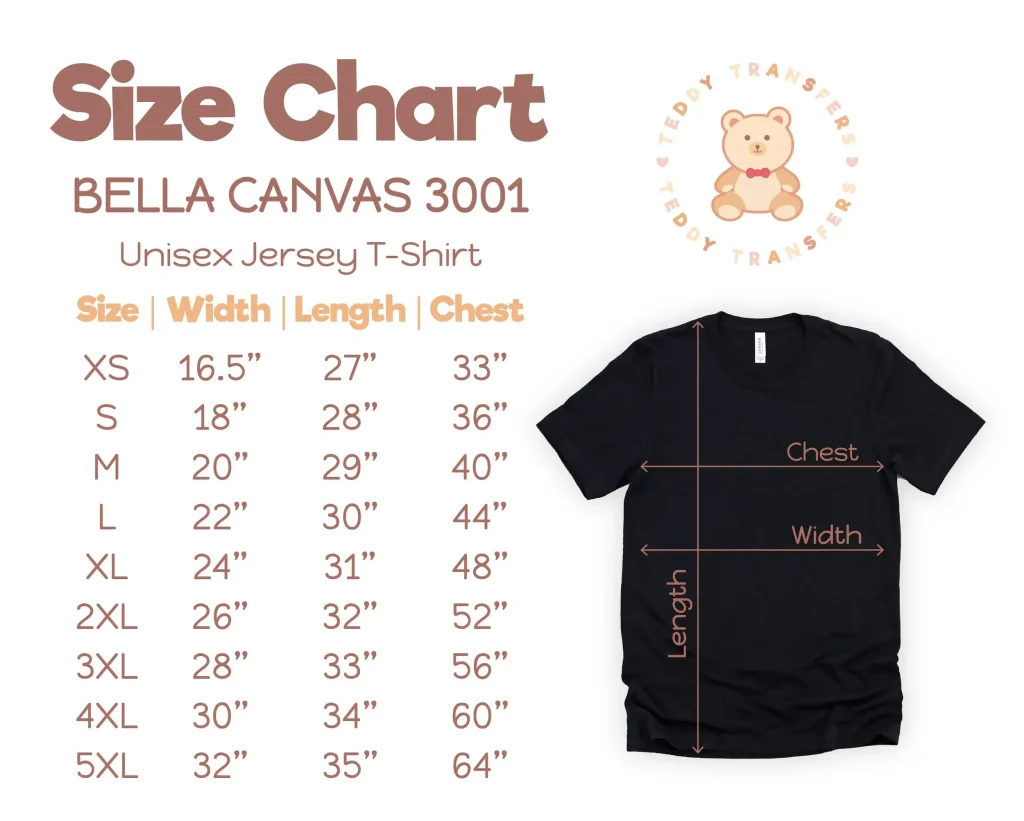

DTF transfer sizes vary to accommodate various garment styles and design dimensions. Commonly available sizes include A4, A3, and custom sizes tailored to specific projects. When choosing a size, consider the design’s placement on the garment and target audience preferences.

How does the size of DTF transfers impact the printing process?

The size of DTF transfers directly influences the effectiveness of the printing process. Properly sized transfers ensure that designs align with fabric dimensions, enhancing visual appeal. Overly large transfers can lead to difficulties during application, while too small transfers might diminish the intended impact.

What are the best practices for selecting DTF transfer sizes for custom printing?

When selecting DTF transfer sizes for custom printing, it’s crucial to test various dimensions to see how they appear on the fabric. Collaborating with print providers to ensure the transfer fits the garment correctly is also a best practice. Always leave a margin for safety during heat application to avoid overexposure.

What trends are influencing DTF transfer sizing in the printing industry?

Current trends in DTF transfer sizing are leaning towards customization and personalization. Many businesses are now offering tailored sizes that meet specific design requirements, allowing for unique garments that stand out in the marketplace. Staying updated on consumer preferences can help businesses remain competitive.

Why is the importance of DTF transfer size crucial for successful designs?

The importance of DTF transfer size lies in its impact on both aesthetics and functionality. Well-sized transfers enhance the visual appeal of designs on apparel while ensuring that they withstand the rigors of wear. A transfer that’s too big or too small can compromise the finished product, making proper sizing essential.

How can I find the perfect fit for my DTF transfer projects?

To find the perfect fit for your DTF transfer projects, consider the garment’s specific dimensions, your design elements, and your audience’s preferences. Collaborating with your print vendor and experimenting with various sizes can also help achieve the best results for your custom DTF transfers.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF transfers use heat and pressure to apply prints to fabric, allowing for vibrant designs and personalization. |

| Sizing Importance | The size of the transfer affects aesthetics and functionality; it must match garment dimensions. |

| Design Space Matching | Proper alignment with the designated area enhances the visual appeal and cohesiveness of the design. |

| Margin of Safety | Including a margin around the design prevents overexposure during the heat application process. |

| Audience Consideration | Understanding target demographics helps in choosing the right designs—bold for sportswear, subtle for casual wear. |

| Current Trends | A shift towards bespoke sizing solutions is evident, boosting customer satisfaction and differentiation. |

| Best Practices | Collaboration with print providers and testing various sizes improve final product quality. |

| Future Outlook | Emphasis on tailored transfer sizes will continue to grow, adapting to market trends and consumer needs. |

Summary

DTF transfer sizes are crucial for the success of any design project, directly affecting quality and consumer satisfaction. By understanding the nuances of sizing, including the matching of design space, maintaining safety margins, and aligning with audience preferences, businesses can enhance their product offerings. Staying updated with industry trends and collaborating with print providers ensures that each DTF transfer is executed flawlessly. As this technology evolves, the focus on customized DTF transfer sizes will remain pivotal in meeting the demands of a dynamic market.