DTF Transfer by Size stands as a cornerstone concept in direct-to-film printing, shaping the final appearance of any garment. The size you choose during design and transfer influences color accuracy, edge sharpness, and wearability, and ignoring this can amplify common DTF printing mistakes. A thoughtful, size-aware approach helps artwork stay crisp and shop-ready across different garments, with benefits for consistency and customer confidence, guided by a DTF by size guide. To keep outcomes predictable, prioritize DTF Transfer by Size when setting alignment, applying heat press settings, and choosing substrates. This brief introduction sets the stage for practical steps to avoid errors and scale designs reliably across sizes.

Beyond the exact label, you can frame this as a dimension-based transfer where artwork scales thoughtfully to fit different garment surfaces. LSI-friendly terms like size-aware design, scale-optimized placement, and alignment accuracy guide how you adapt prints for curves, seams, and product photography. This approach helps reduce distortion, supports consistent color management, and informs heat press settings across sizes. Practically, you map artwork to multiple scale options, test edge definition at each size, and document size-specific tolerances to keep your catalog cohesive.

1) Understanding DTF Transfer by Size: The Foundation for Consistent Results

DTF Transfer by Size is a foundational concept in direct-to-film printing that shapes every downstream detail of the finished garment. The size you select for a transfer influences color accuracy, edge sharpness, and overall wearability, especially when moving from a simple logo to a full-front print. A size-aware approach helps preserve line work, color density, and texture, ensuring artwork reads clearly in product photography and in real-world use. By treating size as a design parameter rather than a post-production afterthought, you create predictable outcomes that scale across multiple SKUs and stock programs.

In practice, a size-driven workflow means planning notes, templates, and quality checks that explicitly address the intended output size. The planning stage should spell out the expected output for each garment size, and teams should reference DTF by size guide materials to prevent drift between small, medium, and large formats. This approach reduces variability in alignment, edge definition, and color performance, and it builds a repeatable process that supports growth while maintaining a consistent customer experience.

2) Common DTF Printing Mistakes and How Size Affects Them

DTF printing mistakes can escalate when size is not managed carefully. Common errors like mis-sizing and cropping, poor alignment, and unresolved resolution or color management problems often stem from failing to preserve aspect ratio or misapplying a design to larger substrates. Such issues manifest as stretched or cropped elements, visible halos, or edge artifacts that undermine overall product quality. By recognizing how size amplifies these problems, teams can anticipate trouble and implement safeguards at the design and pre-press stages.

To minimize risk, adopt size-specific checks that tackle each category of error. Use safe margins and placement guides for every target size, maintain aspect ratios, and engage in color profiling that translates consistently from screen to print across sizes. Documented size-based QA points—covering placement accuracy, edge crispness, and adhesion—help catch discrepancies early and prevent incompatible results from slipping into production.”]},{

3) Mastering DTF Alignment: Techniques for Size-Specific Accuracy

DTF alignment errors are among the most visually jarring issues, particularly when a large print spans seams or moves across curved areas of a garment. Mastering alignment requires reliable marks, corner tabs, or a jig, plus a disciplined approach to multi-pass placements for larger formats. By implementing size-aware alignment practices, you ensure that the print remains centered and proportional from XS to XXL, reducing the risk of skew or off-center imagery that harms the garment’s presentation.

Practical alignment methods include using a two- or three-point system for larger designs, consistent markers across sizes, and standardized loading procedures that minimize movement during press. Elevate accuracy by pairing alignment checks with templates that show exact distances from key reference points (collar seams, center front, hem). Regular audits of alignment across sizes help maintain a cohesive look that customers recognize as brand-consistent.

4) Optimizing DTF Heat Press Settings Across Size Ranges

DTF heat press settings must be tuned to both size and substrate. Temperature, time, and pressure interact with fabric weight and weave, so larger transfers often require longer dwell times or higher pressure, while smaller prints may benefit from more controlled, gentler settings. Ignoring size in heat press calibration can lead to incomplete adhesion, edge curling, or color separation that becomes more pronounced on bigger surfaces.

A size-aware approach to heat pressing includes establishing recommended ranges for each size category and substrate type, documenting those settings, and applying them consistently across orders. Regular verification with test swatches for every size helps catch drift early. Consider implementing a lightweight calibration protocol that evaluates adhesion at center and edges per size to ensure uniform results before running bulk production.

5) DTF By Size Guide: Templates, Measurements, and QA for Every Size

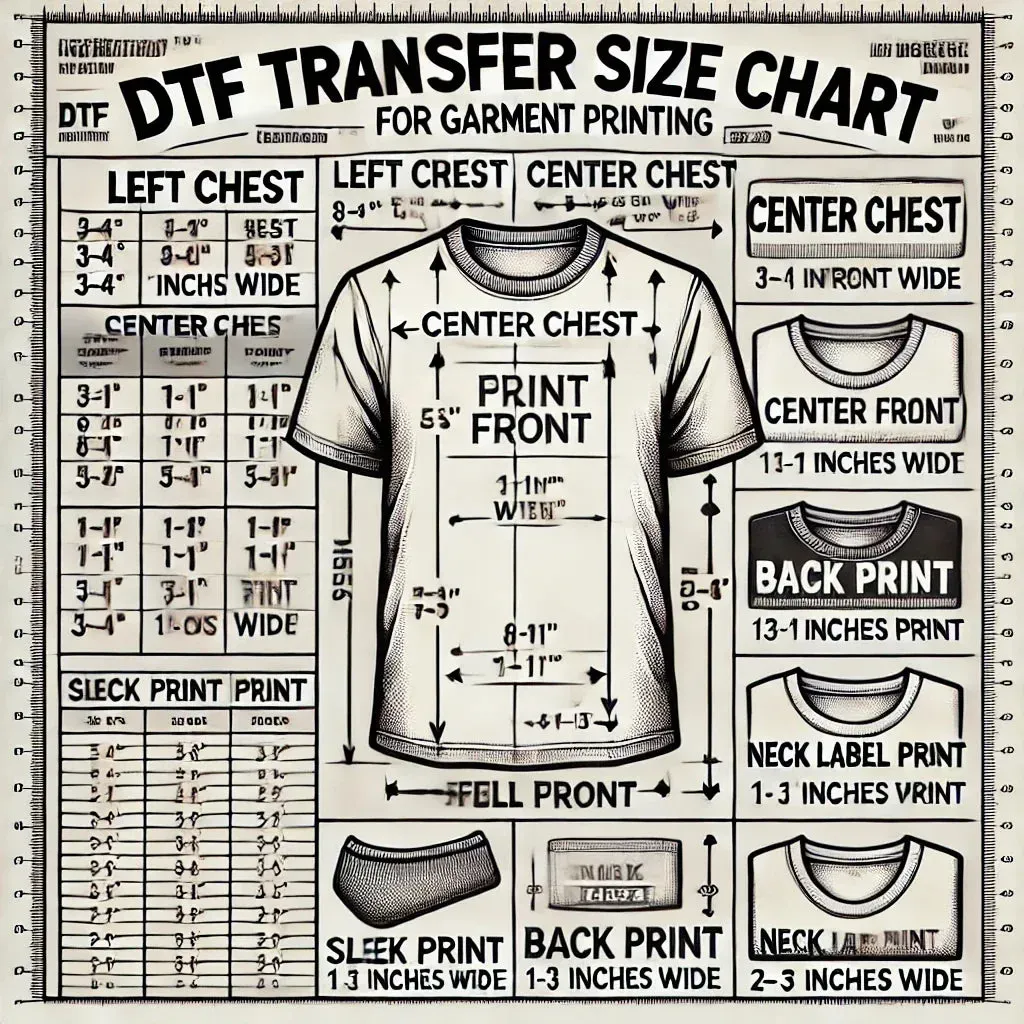

DTF by size guide materials act as the backbone of a scalable production system. Templates that include safe margins, bleed areas, and precise placement guides reduce variability and accelerate handoffs between design, pre-press, and production teams. By using size-specific templates, you prevent disproportionate scaling that can blur details or distort edges, and you maintain consistent print fidelity from small to large formats.

A robust by-size QA program complements templates by providing explicit checks for each size. This includes color management across sizes, per-size swatches for validating color fidelity, and a size-based checklist covering placement, edge sharpness, adhesion, and durability. Integrating the DTF by size guide into standard operating procedures helps ensure that every batch meets brand standards and that customers receive uniform quality across product lines.

6) Practical Workflows: A Size-Driven Step-by-Step Path from Design to Delivery

A size-driven workflow begins at design and continues through press and post-press steps, with explicit attention to how each size will render on the target garment. Start by preparing artwork at the correct size, using placement guides and safe margins. Print on calibrated equipment for the intended sizes, powder and cure correctly, and then pre-press to create a flat surface before applying the transfer. This lifecycle helps preserve edge clarity and color fidelity across all sizes.

Maintain rigorous documentation of size-specific adjustments, and run small-scale tests in each target size before committing to full production. This practice protects against scale-induced issues and provides a clear trail for QA and future improvements. By documenting lessons learned and updating the DTF by size guide, templates, and heat press profiles, your operation can scale with confidence while delivering consistently high-quality garments across a full size range.

Frequently Asked Questions

What is DTF Transfer by Size and why does choosing the right size matter for DTF transfers?

DTF Transfer by Size is the practice of matching transfer sheet dimensions to the garment surface. The size you choose affects color accuracy, edge sharpness, and wearability, so using a size‑aware planning process keeps artwork crisp and consistent across orders.

How do DTF printing mistakes relate to transfer by size, and what steps reduce them?

Many DTF printing mistakes arise from sizing errors, such as cropping or misplacing designs across sizes. Reducing them involves using size templates, reviewing aspect ratios, and verifying placement for each size to improve consistency.

What are DTF alignment errors, and how can size-aware alignment prevent them?

DTF alignment errors occur when a transfer isn’t positioned consistently, especially across different sizes. Prevent them with alignment aids (markers, corner tabs, or a jig) and per‑size placement guidelines to keep edges and centers aligned.

How should you tailor DTF heat press settings for different sizes?

DTF heat press settings should be tuned to the garment size and fabric. Establish size‑specific temperature, time, and pressure ranges, calibrate with tests, and document results to ensure even adhesion across small, medium, and large prints.

What is a DTF by size guide and how does it support scalable designs?

A DTF by size guide provides templates, safe margins, bleed areas, and placement rules for XS through XXL. It helps preserve detail, prevents cropping, and maintains consistent print quality across sizes.

What steps constitute a size-driven workflow to minimize DTF transfer by size issues?

Adopt a size‑driven workflow: create size templates, maintain aspect ratios, generate size‑specific assets, use alignment aids, calibrate heat press settings by size, manage color consistently, perform per‑size pre‑press checks, run small-scale tests, and maintain a size‑based QA checklist. This helps reduce DTF printing mistakes and DTF alignment errors while ensuring reliable adhesion.

| Key Point | Why It Matters | Practical Tip |

|---|---|---|

| DTF Transfer by Size | Defines how transfer sheet dimensions interact with the garment surface and affects color accuracy, edge sharpness, and wearability. | Plan with size templates and document planning notes that include DTF Transfer by Size; use size matching templates and QA checks. |

| Mis-sizing and Cropping | Can cause distortion and a mismatched look across sizes; important elements can be cropped. | Preserve aspect ratio, provide safe margins, and verify vertical placement for different sizes. |

| Poor Alignment and Placement | Misalignment ruins visual impact and fidelity, especially on larger prints or varying sizes. | Use alignment marks, corner tabs, or a jig and keep markers consistent across sizes. |

| Resolution and Color Management | Scaling can cause jagged edges and color shifts, more noticeable on larger prints. | Use size-specific assets, maintain color profiles, and test swatches for each size. |

| Inadequate Pre-Press and Substrate Prep | Wrinkles or moisture can affect adhesion, especially on larger transfer areas. | Pre-press thoroughly, ensure flatness, and manage moisture per size. |

| Inconsistent Heat Press Settings | Temperature, time, and pressure must match the size and garment type to avoid adhesion issues. | Calibrate heat press settings by size and document them for consistent application. |

| Inadequate Curing and Adhesive Behavior | Uneven curing can cause edge faults and inconsistent adhesion across large areas. | Ensure uniform curing, monitor adhesive performance across sizes, and adjust as needed. |

| How to Avoid These Mistakes (Size-Focused) | A repeatable workflow that embeds size awareness at every stage reduces errors. | Use size templates, review aspect ratios, generate size-specific assets, apply alignment aids, calibrate heat settings, manage color, perform thorough pre-press, run small tests, and maintain a size-based QA checklist. |

| Practical Size-Specific Practices for Different Garment Types | Garments respond differently to size and curvature varies placement and edge behavior. | Small designs: crisp edges; Medium: balanced margins; Large: careful alignment; for curved areas use relaxed tension. |

| Step-by-Step Workflow for Size-Driven DTF Transfers | A clear sequence helps ensure consistency across sizes. | 1) Prepare artwork at correct size with margins, 2) Print, 3) Powder and cure, 4) Pre-Press, 5) Align, 6) Apply heat, 7) Peel/Cool, 8) Inspect, 9) Document size-specific adjustments. |

| Troubleshooting by Size | Provide quick fixes for common size-related problems. | Edge adhesion: adjust dwell or pressure; Color: test swatches; Distortion: adjust size templates; Fading: adjust heat settings. |

| Bottom Line | Size-aware planning drives consistency and quality across products. | Use templates, alignment, color management, and QA to scale across sizes. |

Summary

DTF Transfer by Size is a foundational workflow that shapes how artwork translates to fabric across every size. When you plan and execute transfers with size in mind, you achieve consistent edge clarity, accurate color, and dependable wearability from XS to XXL. A size-aware process—supported by templates, alignment aids, calibrated heat settings, robust color management, and thorough pre-press and QA—reduces mistakes, increases efficiency, and scales your DTF business with confidence. By documenting size-specific adjustments and continuously refining your workflow, you can deliver shop-ready designs that look intentional and perform reliably on a range of garments.