Creating stunning designs with a UV DTF gangsheet builder is revolutionizing the way designers approach printing. This advanced technology merges the precision of UV printing with the flexibility of gangsheet layouts, allowing artists to produce vibrant, high-quality prints efficiently. With UV DTF printing, every design can be magnified in detail and color depth, enhancing the overall impact of the finished product. By utilizing a gangsheet builder, designers can organize multiple graphics seamlessly on one sheet, streamlining their workflow and reducing material waste. This introduction underscores the importance of embracing modern printing techniques that not only elevate the design process but also meet the growing demand for stunning visuals in various applications.

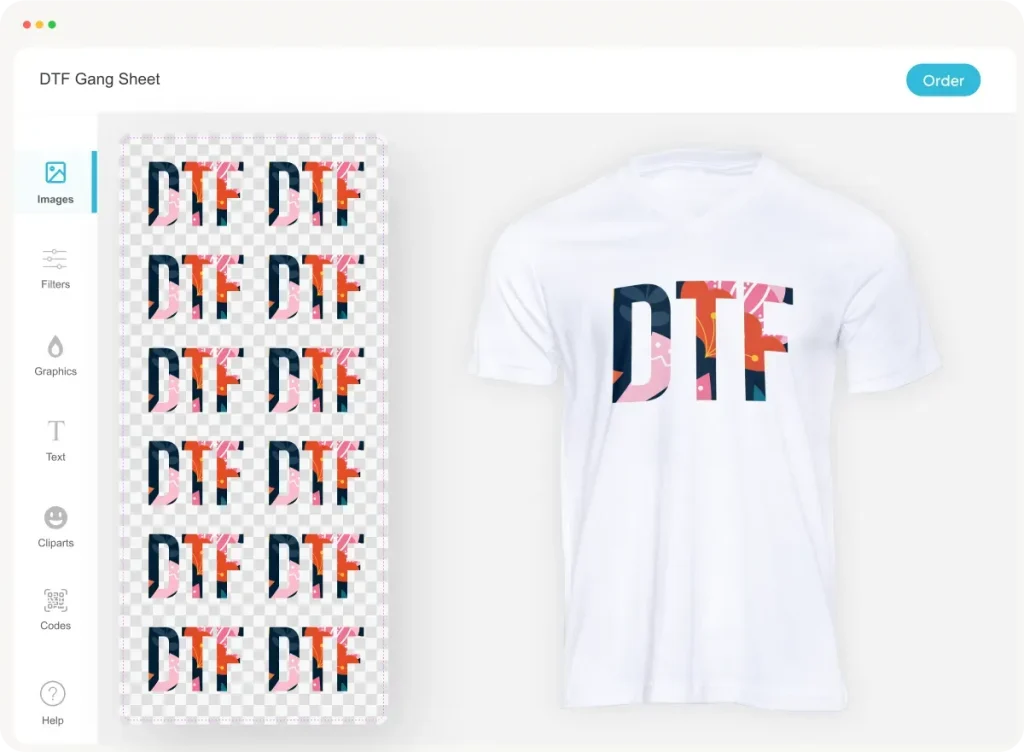

In the realm of innovative printing, the use of a UV Direct to Film gangsheet creator is setting new standards for quality and efficiency. This cutting-edge method transforms the way artwork is printed, providing an array of options that cater to various surfaces. Designers can harness this unique printing technology to generate eye-catching graphics while optimizing the arrangement of multiple designs on a single print sheet. By mastering the art of heat transfer printing with a gangsheet approach, creators can achieve unparalleled results that not only captivate audiences but also facilitate a more economical production process. Explore how this remarkable tool is reshaping the design landscape and empowering artists to bring their visions to life.

Understanding UV DTF Printing Technology

UV DTF printing technology has revolutionized how designers create intricate and vibrant designs. Using ultraviolet light to cure inks directly onto a film substrate, this method provides a superior quality print compared to traditional heat transfer methods. The process allows for sharp details and bright colors, which are essential for attracting and retaining customer interest. By leveraging the latest in UV technology, manufacturers can produce high-quality prints that stand the test of time, making it a preferred choice in various industries.

Moreover, UV DTF printing is highly versatile as it accommodates different types of materials. Whether you’re working with fabrics, plastics, or even wood, the UV inks can adhere effectively, providing endless possibilities for customization. This printing technology is not just about functionality; it also offers designers a canvas to express creativity while delivering outstanding results. With its ability to maintain vibrancy and detail, UV DTF is quickly becoming the industry standard.

Benefits of Using a UV DTF Gangsheet Builder

The UV DTF gangsheet builder is a game-changer for modern printing projects. One of the most significant advantages is its cost efficiency. By allowing multiple designs to be printed on a single sheet, it minimizes waste and maximizes the usage of materials. This means that designers can produce more prints in one go, reducing production costs and increasing profit margins. Additionally, the software often includes layout optimization tools that help arrange graphics in a manner that maximizes space, further driving down expenses.

Another key benefit of the UV DTF gangsheet builder is the time savings it offers in the design and production process. With an organized setup, designers can quickly import and position their artworks, facilitate faster printing, and reduce the overall turnaround time. These efficiency gains enable printing businesses to handle larger volumes of work while maintaining high-quality outputs. In a fast-paced industry, where time translates to money, this tool has proven invaluable.

A Step-by-Step Guide to Using a Gangsheet Builder

To effectively utilize a UV DTF gangsheet builder, one must begin with creating a well-structured design in professional graphic design software. The first step is to establish the correct dimensions and resolutions suited for the final print materials. Designers need to consider color fidelity and other effects that resonate with their target audience. Once the design is ready, it can be seamlessly imported into the gangsheet builder, ready to be positioned alongside other designs.

Subsequently, the gangsheet builder optimizes the layout by allowing designers to adjust the spacing and alignment of their graphics. This precise arrangement is critical for achieving high print quality while minimizing waste. After finalizing the layout, the user can proceed to print on the specially coated DTF film. Following the print, curing the design under UV light ensures vibrant colors and lasting durability, making this an essential process in achieving stunning results.

Recent Trends in UV DTF Technology

As UV DTF technology continues to evolve, new trends are emerging that promise to enhance the printing experience. One notable trend is the development of sophisticated software tools integrated into gangsheet builders. These tools not only streamline the design process but also incorporate functions for color matching and asset management, catering to a collaborative environment. By equipping designers with advanced functionalities, these modern tools help maintain consistency and quality across printing projects.

Additionally, advancements in UV DTF technology have expanded the range of printable materials. Designers are no longer limited to traditional substrates; they can experiment with leather, wood, and more unconventional surfaces. This evolution enables creatives to explore and push the boundaries of their designs, opening new avenues for artistic expression. As the availability of these materials increases, so does the potential for creating unique, one-of-a-kind products that stand out in the market.

The Importance of Curing in the UV DTF Process

Curing is a critical step in the UV DTF printing process that must not be overlooked. It involves exposing the printed film to UV light, which sets the ink and ensures the durability of the output. This step solidifies the bonds between the ink and the substrate, producing a robust print that can withstand everyday wear and tear. Without proper curing, printed designs may fade, crack, or peel over time, undermining the quality and longevity that UV DTF printing is known for.

Moreover, the curing process also affects the vibrancy of the colors on the printed surface. When expertly executed, curing enhances the visual appeal of the design by bringing out the richness of the colors and the clarity of details. As such, a well-cured print not only looks stunning but also lives up to customer expectations for quality, making it essential for any printing business aiming to maintain high standards.

Frequently Asked Questions

What is a UV DTF gangsheet builder and why is it important in the design process?

A UV DTF gangsheet builder is a specialized tool that allows designers to efficiently arrange multiple designs on a single print sheet. It plays a crucial role in the design process by maximizing material usage, reducing waste, and streamlining the workflow for UV DTF printing.

How does UV DTF printing differ from traditional heat transfer printing techniques?

UV DTF printing differs from traditional heat transfer printing in its use of UV inks that cure under UV light, resulting in vibrant colors and sharp details. Unlike conventional methods that may fade over time, UV DTF provides more durable prints suitable for various substrates.

Can I use the gangsheet builder for printing on materials other than fabric?

Absolutely! The gangsheet builder is versatile and allows prints on various substrates, including wood, leather, and synthetic materials. This flexibility opens up new creative possibilities for stunning designs using UV DTF printing.

What are the steps involved in using a UV DTF gangsheet builder for print production?

The steps include designing your graphics, importing into the gangsheet builder, optimizing layout for material use, printing on coated DTF film, curing the print with UV light, transferring onto the desired substrate, and finalizing with post-print treatment for enhanced durability.

What are the benefits of using UV inks in the printing technology supported by a gangsheet builder?

UV inks provide high-color vibrancy, quick curing times, and exceptional durability, which helps in maintaining the quality of designs over time. Using a gangsheet builder with UV inks ensures cost efficiency and time savings while delivering stunning prints.

How has recent technology advancement improved the use of gangsheet builders in UV DTF printing?

Recent advancements in technology have led to more sophisticated gangsheet builders that offer improved layout tools, better color matching, and integration with digital asset management systems, enhancing design efficiency and collaboration among printing teams.

| Step | Description |

|---|---|

| 1. Design Creation | Use design software like Adobe Illustrator or CorelDRAW to create graphics. |

| 2. Using the Gangsheet Builder | Import designs, optimize layout to minimize waste, and ensure proper alignment. |

| 3. Printing on Film | Print your optimized designs on a specially coated DTF film for vibrant adhesion. |

| 4. Curing the Print | Cure the prints using UV light to set the ink for durability. |

| 5. Transfer Process | Use heat and pressure to transfer print onto the desired substrate. |

| 6. Finalizing | Apply post-print treatment for longevity and vibrancy protection. |

Summary

Creating stunning designs with a UV DTF gangsheet builder revolutionizes the design and printing industry by marrying quality with efficiency. This innovative technology empowers designers to craft vibrant prints on a rich array of materials, enhancing their creative potential. The step-by-step process—from design creation to final post-treatments—ensures that every phase is streamlined to maximize output while minimizing costs. By embracing the advancements in UV DTF technology, designers can produce artworks that not only captivate their audience but also stand the test of time, breathing life into their visions. As the industry continues to evolve, utilizing a gangsheet builder becomes not just a choice, but a necessity for those looking to stay ahead in the ever-competitive landscape.