When it comes to garment printing techniques, **DTF transfer size** is a crucial aspect that can make or break the quality of your finished product. Selecting the appropriate transfer size ensures that your design stands out and aligns perfectly with your project requirements. In this guide, we will delve into expert **DTF printing tips**, helping you choose the right size based on factors such as fabric type, garment dimensions, and the intricacy of your DTF transfer design. Understanding these considerations not only enhances the aesthetic appeal but also curtails the possibility of design distortion during the printing process. Join us as we explore how to perfect your print projects by mastering the art of DTF transfer sizing.

In the world of garment decoration, selecting the right size for your **direct-to-film** transfers is pivotal for achieving optimal visual results. The term “transfer dimensions” refers to the specific measurements of designs printed onto film, which are later heat-pressed onto fabrics. As you embark on your printing endeavors, keeping in mind various factors such as fabric weight, artwork detail, and market trends will guide you in arriving at the perfect sizing choice. From smaller patterns suitable for children’s apparel to larger prints that capture attention on sweatshirts, understanding the nuances of transfer sizing is essential. This article highlights practical strategies for ensuring your designs translate flawlessly onto any garment.

Understanding the Basics of DTF Transfers

DTF transfers are revolutionizing the garment printing landscape by enabling vivid designs to be applied to various fabrics with ease. The essence of DTF printing lies in its ability to adhere to multiple fabric types, making it a versatile choice for garment decorators. For anyone venturing into this printing technique, grasping the fundamentals is crucial. It helps you appreciate how color vibrancy, detail retention, and longevity of your designs interplay with the chosen transfer size.

Moreover, understanding DTF transfers also includes recognizing their characteristics, such as flexibility and durability. These qualities allow for intricate designs without compromising the fabric’s texture and feel. Several factors, including how the transfer blends with the garment’s fabric and the intended use of the printed item, must be considered, making education on DTF printing vital for successful printing projects.

Choosing DTF Transfer Size: A Practical Approach

Choosing the right DTF transfer size is fundamental to achieving the desired aesthetic and functionality in your projects. One practical starting point is to reference established size guidelines based on the garment type and intended audience. For instance, children’s clothing typically benefits from smaller, more discreet designs, whereas adult apparel can showcase larger transfers that make a bold statement. Keeping these considerations in mind ensures that your designs remain proportional and visually appealing.

Additionally, it’s wise to utilize templates or mockups when deciding on DTF transfer sizes. These tools can help you visualize how your design interacts with various fabric types and garment styles, enabling you to make informed choices. Such preparation pays off significantly by avoiding costly mistakes typically incurred through poorly sized transfers.

Impact of Fabric Type on DTF Transfer Size Selection

The type of fabric you select for your garment profoundly impacts the size of the DTF transfer you choose. For heavier fabrics like canvas or denim, larger transfers are generally permissible and can create eye-catching designs without losing quality. These materials are sturdy enough to support bold visuals and intricate patterns, enabling creative freedom in your printing projects.

Conversely, lighter fabrics, such as cotton t-shirts, may only be suited for smaller, more subtle transfers. Large prints on delicate fabrics can easily become overwhelming, potentially detracting from the garment’s overall appeal. Therefore, aligning your DTF transfer size with the fabric type ensures not only aesthetic harmony but also enhances the durability and comfort of the printed piece.

Evaluating Garment Sizes for Optimal DTF Transfer Fit

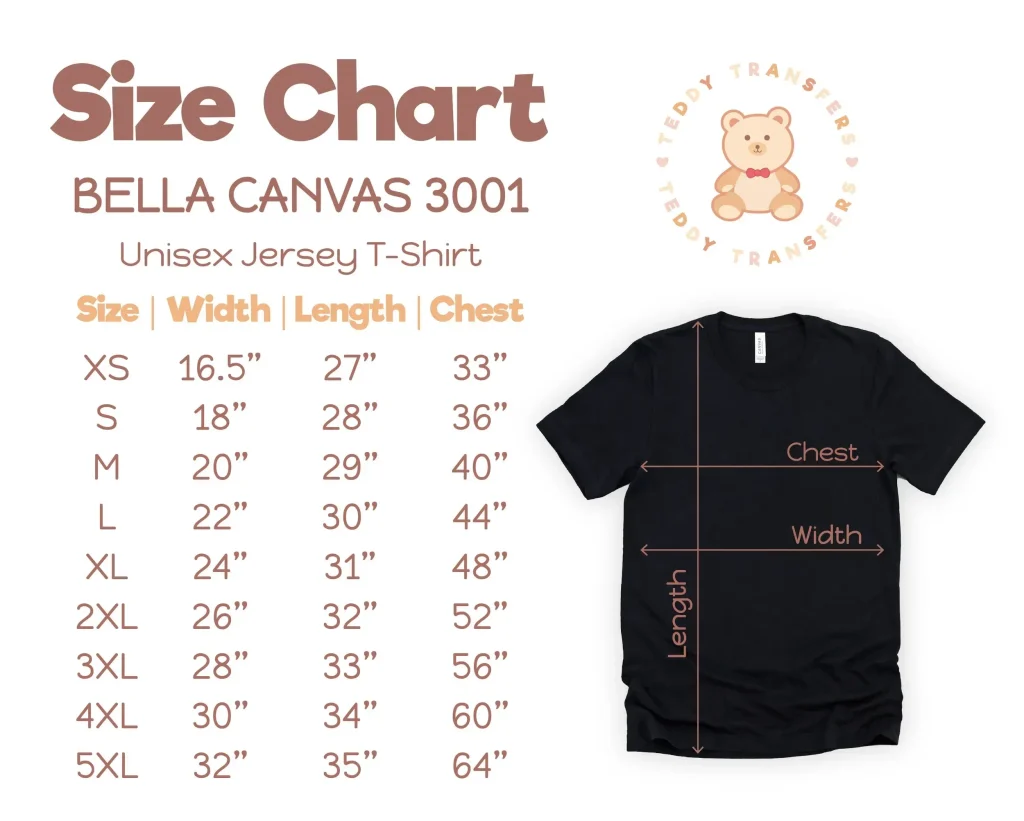

Garment size is another essential factor in determining the appropriate DTF transfer size. Different demographic groups require size considerations that match their needs. For example, kids’ clothing often necessitates smaller transfers to fit the dimensions of youth apparel, while larger sizes are more fitting for adult garments. An awareness of these nuances can significantly enhance the effectiveness of your design and increase buyer satisfaction.

Additionally, considering specific garment cuts and styles—such as fitted versus oversized—adds another layer of complexity. Evaluating various sizes through mockups allows you to gauge the effectiveness of your transfer at different scales. By assessing different garment sizes, you ensure that the DTF transfer looks balanced and proportionate across the range of products.

Growing Trends in DTF Transfer Design Sizes

Staying attuned to fashion trends is also vital when choosing DTF transfer sizes. Current consumer preferences lean towards more minimalistic designs that typically favor smaller transfer sizes. This shift not only reflects a change in aesthetic choice but also aligns with functionality, allowing designs to integrate seamlessly with the overall garment.

Understanding these market trends empowers garment printers to tailor their offerings accordingly. Researching popular clothing lines and consumer preferences can provide insights into what sizes and styles resonate with today’s audiences. Being proactive in aligning your DTF transfer sizes with these trends will greatly enhance customer satisfaction and can lead to increased sales.

Printer Specifications and DTF Transfer Capability

When embarking on your DTF printing journey, understanding the specifications of your printer is essential for successful project execution. Each DTF printer comes with its own set of capabilities, particularly regarding maximum and minimum transfer sizes it can handle. Being informed about these limitations can save time and resources, preventing issues like misalignment or quality degradation in the final print.

In addition to printer size capabilities, consider factors like print resolution and material compatibility. Knowing your equipment’s strengths and limitations helps in making informed decisions about DTF transfer sizes that align harmoniously with both the printer’s abilities and your design goals, ultimately leading to high-quality finished products.

Frequently Asked Questions

What factors should I consider when choosing DTF transfer size for my garments?

When choosing the right DTF transfer size for your garments, consider factors such as the intricacy of your design, the fabric type, the size of the garment, and current market trends. High-resolution artwork is essential, as is understanding how larger transfers can overwhelm smaller garments. Additionally, keep your target demographic in mind, as their preferences will impact your size selection.

How does fabric type affect DTF transfer size selection?

Fabric type plays a crucial role in determining the appropriate DTF transfer size. Heavier materials, like denim and canvas, can accommodate larger transfers without compromising quality. In contrast, lighter fabrics, such as cotton or polyester, may benefit from smaller, less overpowering designs that complement the garment rather than dominate it.

What are some DTF printing tips for achieving the best results with transfer sizes?

To ensure the best results with DTF transfer sizes, use high-resolution designs, evaluate the garment size, and consider the fabric type. Additionally, familiarize yourself with your DTF printer’s specifications regarding transfer sizes to prevent misalignment and ensure quality. Staying updated on market trends can also inform your size selection for optimal client satisfaction.

Can I use larger DTF transfers on children’s clothing?

It is generally not advisable to use larger DTF transfers on children’s clothing, as they can overwhelm smaller garments. Instead, opt for smaller transfer sizes that maintain an appropriate balance and visibility on these items. Always consider the proportion of the design to the garment size for a visually appealing outcome.

How do I determine the ideal DTF transfer size for intricate designs?

For intricate designs, the ideal DTF transfer size will often be smaller. This helps maintain the clarity and detail of your artwork, preventing blurring or distortion during the printing process. Analyze the level of detail in your design before deciding on a transfer size to ensure that your final prints are high-quality.

What market trends should I consider when selecting DTF transfer sizes?

Current market trends indicate a preference for minimalistic styles, often leaning towards smaller DTF transfer sizes. Understanding these trends is essential, as it allows you to align your designs with customer preferences, ensuring higher satisfaction rates and better sales outcomes in your printing projects.

| Consideration | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers print designs on film to be heat-pressed onto fabric, requiring attention to transfer size for quality results. |

| Design and Artwork Considerations | Consider resolution and detail, placement on garments, and ensure high-resolution and clarity without overwhelming the design. |

| Fabric Type and Weight | Heavy fabrics can handle larger transfers, while lighter fabrics benefit from smaller designs that enhance the overall aesthetic. |

| Garment Size | Children’s clothing needs smaller transfers while adult sizes can accommodate larger designs. |

| Application Method | Know your printer’s specifications to avoid misalignment and poor-quality prints. |

| Market Trends and Client Preferences | Stay updated on trends to meet customer preferences, often favoring minimalistic designs and smaller transfer sizes. |

Summary

DTF transfer size is crucial for ensuring high-quality results in printing projects. By carefully considering design intricacy, fabric types, garment size, application methods, and market trends, you can effectively choose the right DTF transfer size that not only enhances the visual appeal of your designs but also caters to the functional needs of the fabric. A well-thought-out approach will ultimately result in products that exceed expectations and resonate with customers.