DTF transfer sizing is a crucial aspect of the DTF printing process that can significantly impact the quality of your prints. This innovative technique allows for vibrant designs and intricate details to be transferred seamlessly onto various materials, making it the go-to choice for custom garment creation. However, understanding the nuances of sizing DTF transfers is essential to ensure your designs not only look good but also adhere properly and maintain their quality over time. In this article, we will delve into the importance of proper sizing when designing for garments, exploring effective strategies and techniques that can help you achieve stunning results with your DTF transfers. Join us as we uncover the best practices for optimizing your prints through careful sizing considerations and techniques.

When it comes to fabric transfer printing, sizing plays an indispensable role in ensuring your designs meet the desired quality and aesthetic standards. Direct to Film (DTF) printing has quickly become a popular method for creating customized apparel, but achieving the right scale for your images is vital. From adjusting dimensions to fit various garment sizes to ensuring proper alignment during the transfer process, mastering the art of estimating sizes for DTF transfers is paramount. This exploration into effective sizing strategies will provide you with insights that not only enhance the visual appeal of your garments but also improve the longevity of your prints. Let’s embark on a comprehensive guide to mastering the intricacies of sizing for successful DTF printing.

Understanding DTF Printing Techniques

DTF printing, or Direct to Film printing, employs a specialized process that allows vibrant designs to be printed on a transfer film before being applied to fabric. This technique is particularly favored for its adaptability, enabling users to transfer intricate images on various materials, from cotton blends to polyester. The DTF transfer method involves precise temperature and pressure control, ensuring that the ink adheres properly to the fabric, resulting in a high-quality finish that stands up to repeated washing.

The essence of effective DTF printing lies in mastering printing techniques, from preparing the artwork to adjusting printer settings. Professionals commonly utilize high-resolution images that can maintain clarity when printed large. The choice of inks—typically water-based—also plays a critical role, as they are designed to bond with the film, ensuring that the design remains vibrant and intact after the transfer process.

Importance of Sizing in DTF Transfers

In the realm of DTF printing, sizing cannot be underestimated. Incorrect sizing can result in designs that either dominate the garment ineffectively or fade into obscurity. For successful DTF transfers, it’s essential to find a balance where the graphic complements its fabric without overwhelming or underwhelming it. Furthermore, maintaining proportional sizing ensures that the integrity of the design remains intact, leading to more aesthetically pleasing results.

Misalignments, caused by improper sizing, can prove costly—both in materials and time. With DTF, a well-proportioned design will not only enhance the garment’s overall look but can also extend the life of the transfer. A design that doesn’t align does not just detract from appearance; it can also compromise the durability of the print itself, resulting in peeling or fading after laundering.

Best Practices for Sizing DTF Transfers

To optimize DTF transfer sizing, employing best practices is vital. One of the primary steps includes using garment templates provided by manufacturers, which serve as guides for ideal print dimensions. These templates allow designers to visualize how the graphic will fit on various clothing sizes, ensuring both alignment and proportion accuracy. Taking advantage of these resources can save both time and material expenditure.

Additionally, integrating digital tools into the DTF printing process can significantly enhance the sizing accuracy. Software such as Adobe Illustrator and specialized DTF programs allow for precise resizing and manipulation of designs to fit specific garment areas. With user-friendly interfaces, these programs provide options to experiment with layouts, colors, and sizes until achieving the perfect look.

Conducting Test Prints for Optimal Results

Conducting test prints is a critical phase in the DTF printing process. Before committing to extensive runs, creating samples ensures that the printed design fits the intended garment size accurately. Test prints not only provide a visual confirmation of size but allow for adjustments in alignment and placement, ultimately leading to a more polished final product.

These preliminary prints are extremely beneficial for evaluating both the aesthetic and functional aspects of the DTF transfer. By inspecting test prints against the actual garment, designers can discern nuances that might otherwise go unnoticed, such as potential misalignments or sizing errors. Armed with these insights, adjustments can be made, safeguarding the quality of the final output.

Choosing Materials That Complement Sizing DTF Transfers

The choice of materials directly impacts the effectiveness of DTF transfer sizing. Various films and inks are available, each with unique properties that can influence the overall quality of the print. Opting for high-quality DTF film ensures that the transfer adheres well to various fabrics, maintaining integrity through wear and washing cycles. Likewise, selecting the right inks plays a crucial role in ensuring vibrant, lasting color post-transfer.

Compatibility between the chosen film, ink, and fabric is paramount. Not all inks adhere well to all fabrics, and understanding these relationships can prevent issues such as bubbling or peeling, which might occur if incompatible materials are utilized. By focusing on selecting the right components for DTF transfer projects, printers can optimize the size and quality of each output.

Final Thoughts on DTF Transfer Sizing

Achieving the right sizing in DTF transfers is essential for delivering high-quality prints that resonate with customers. By understanding the nuances of DTF printing, employing best practices, and selecting appropriate materials, printers can ensure that their designs stand out for all the right reasons. Insights gained from consistent test prints help refine the sizing process, leading to spectacular results.

Ultimately, it is the careful consideration of each aspect—from design and material selection to the intricacies of DTF transfer sizing—that helps you create products that not only meet but exceed client expectations. With diligence and attention to detail, mastering DTF printing can lead to remarkable success in the custom apparel market.

Frequently Asked Questions

What is DTF transfer sizing and why is it important?

DTF transfer sizing refers to the specific dimensions used for designs in DTF (Direct to Film) printing. Proper sizing is crucial because it ensures correct alignment on garments, maintains the proportions of the design, and enhances the durability of the transfer, which impacts the overall quality of the final product.

How do I determine the right size for DTF transfers on different garments?

To determine the right size for DTF transfers on various garments, utilize templates provided by manufacturers, as they offer guidance on ideal print sizes for each apparel type. Additionally, consider performing test prints to evaluate how the design fits and looks on the chosen fabric.

What software can aid in sizing DTF transfers accurately?

Software tools like Adobe Photoshop and CorelDRAW are essential for accurately resizing DTF transfers. These applications allow you to adjust your designs to fit the printable area perfectly, ensuring that your artwork is displayed as intended on the final product.

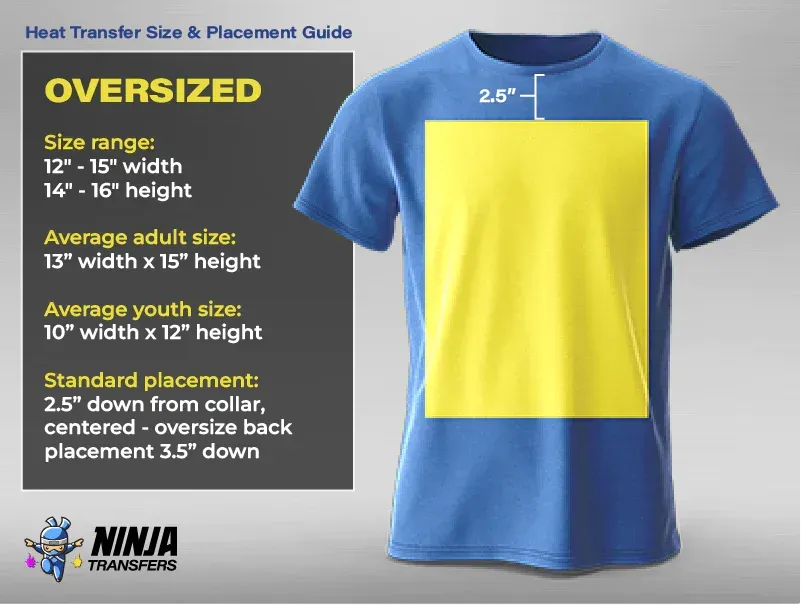

What are common sizes for DTF transfers on garments?

Common sizes for DTF transfers include small prints (3 to 5 inches wide for logos), medium prints (8 to 12 inches wide for larger graphics), and large prints (exceeding 12 inches for full-coverage designs). Choosing the right size is key for achieving the desired aesthetic effect.

How can I ensure the durability of my DTF transfers through proper sizing?

To ensure the durability of DTF transfers, it is important to size the design correctly. If the transfer is too large or small, it might not adhere properly, leading to issues like peeling or bubbling. Additionally, using high-quality DTF films and compatible inks will further enhance durability.

What role does material choice play in DTF transfer sizing?

Material choice plays a significant role in DTF transfer sizing because different fabrics respond uniquely to transfers. High-quality DTF films should be used to ensure they can withstand the heat application process. Consider the compatibility of your ink with the material to achieve vibrant and long-lasting prints.

| Key Point | Description |

|---|---|

| What is DTF Printing? | DTF printing involves printing images on a special film that is heat-pressed onto fabric, allowing for vibrant designs across various materials. |

| Why Size Matters | Incorrect sizing can lead to misalignment, poor proportion, and reduced durability of transfers on garments. |

| Best Practices | Use templates, digital tools, and conduct test prints to ensure correct sizing before full production. |

| Understanding Sizes | Common print sizes: Small (3-5 inches), Medium (8-12 inches), Large (12+ inches) for different design purposes. |

| Choosing Right Materials | Select high-quality DTF film and compatible inks to ensure vibrant, durable prints. |

Summary

DTF transfer sizing is crucial for achieving vibrant and professional prints on various garments. The correct sizing not only enhances the aesthetic appeal of the final product but also ensures proper alignment and durability. By recognizing the significance of accurate sizing in DTF transfers, utilizing templates and digital tools, and conducting thorough test prints, you position yourself to create high-quality DTF designs that resonate with clients. Mastering these techniques in DTF transfer sizing is essential for standing out in the competitive printing market, ultimately leading to products that satisfy customer expectations.