When it comes to DTF transfers, understanding size is essential for achieving high-quality results in custom printing. This method, known for its flexibility and vibrant outcomes, relies heavily on the specifications of transfer sizes to determine its effectiveness. Choosing the right dimensions can not only enhance the detail in your designs but also ensure a perfect fit for various apparel customization needs. As the popularity of DTF printing grows, so does the importance of understanding how different transfer sizes can impact the final product. With advanced DTF technology making customization more accessible, businesses must pay close attention to size to meet diverse customer demands and market trends.

In the realm of Direct-to-Film (DTF) printing, the concept of dimensions and transfer formats plays a pivotal role in the world of personalized designs. Customization options can vary significantly based on the size of the prints, affecting everything from print quality to material compatibility. The latest advancements in DTF technology have introduced a variety of choices, catering to the unique needs of businesses looking to provide tailored solutions in apparel design. As customization continues to thrive in the fashion industry, understanding the significance of transfer dimensions becomes increasingly important for delivering impressive results. This focus on print sizes not only enhances client satisfaction but also empowers businesses to stand out in a competitive market.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing represents a significant advancement in the realm of custom printing solutions. This innovative technology involves printing designs onto a special film before transferring them onto garments. The process allows for vibrant colors and intricate details, making it a preferred choice for businesses seeking high-quality results in apparel customization. With DTF technology, users can achieve stunning outcomes on a variety of materials, enhancing the versatility and appeal of custom prints.

Moreover, DTF printing encourages creativity and flexibility, empowering businesses to meet diverse client needs. By harnessing cutting-edge software and printer capabilities, designers can manipulate size, enabling them to produce tailored transfers for any product. This not only fosters uniqueness in the clothing market but also allows for quick adaptations to seasonal trends or promotional campaigns.

Why Size Matters in DTF Transfers

In DTF transfers, size is more than just a measurement; it fundamentally impacts the quality and effectiveness of the print. Larger transfer sizes often showcase intricate designs and fine details better than their smaller counterparts. The technological capabilities of modern DTF printers are essential in facilitating high-resolution prints without the risk of pixelation, which can occur when larger images exceed the printer’s capabilities.

Conversely, utilizing smaller transfer sizes may limit the visual impact of complex designs. Therefore, understanding the relationship between size and print clarity is key for businesses looking to produce high-quality transfers consistently. By optimizing transfer sizes in accordance with design requirements, businesses can enhance their overall print quality and meet consumer expectations more effectively.

Customization Options with DTF Technology

Customization is a hallmark of DTF technology, allowing for a breadth of options when it comes to apparel decoration. Whether crafting designs for small items like caps or larger textile projects such as backdrops, appropriate sizing is critical for achieving the desired aesthetic appeal. Customization is central to consumer satisfaction, enabling brands to distinguish themselves in the competitive clothing market.

Furthermore, DTF allows businesses to tailor their offerings by producing transfers in diverse sizes that align with customer preferences. This versatility enables clients to select prints that fit not just visually, but also practically onto their chosen garments. Emphasizing customization options helps businesses attract a broader clientele who are searching for personalized apparel that reflects their unique styles.

Material Compatibility and Transfer Sizes

The size of your DTF transfer significantly influences its adhesion and performance on different materials. While larger transfers may excel on smoother fabrics, they may struggle to stick on more textured surfaces. Conversely, smaller transfers can sometimes achieve superior adhesion on challenging materials. Understanding this dynamic is crucial for ensuring that the design remains intact and vibrant over time, supporting the longevity of custom apparel.

Selecting the right size for transfers also impacts the overall look and feel of the finished product. A transfer that is too large may create a cumbersome appearance if not balanced properly with the garment’s dimensions. Achieving the right fit not only elevates the aesthetic appeal but also enhances the wearability of the apparel, reinforcing the importance of size in material compatibility.

Market Trends Impacting Transfer Sizes

The surge in demand for personalized apparel has paved the way for innovative trends in DTF printing. As consumers increasingly seek unique clothing options, businesses utilizing DTF technology must stay abreast of these shifts. Custom-sized transfers, tailored to fit individual preferences, are becoming essential for brands aiming to meet the evolving market dynamics.

By focusing on size variations that resonate with consumer demands, businesses can increase their competitive edge. Additionally, tracking market trends allows companies to fine-tune their product offerings, ensuring they align with consumer interests. Embracing change and adapting to these trends is vital for sustaining success in the increasingly crowded apparel customization landscape.

Balancing Print Quality and Size Efficiency

Achieving the perfect balance between print quality and transfer size is crucial for any DTF operation. Smaller transfers can facilitate faster production times but may compromise the intricacy of designs, leading to simplified visuals. Conversely, larger transfer sizes provide opportunities for elaborate artwork but require more time and precision during the printing process.

To ensure client satisfaction, it’s vital to evaluate the desired level of detail and complexity present in design work. Balancing print quality and size efficiency not only optimizes workflow but also enhances customer experience by delivering impeccably printed products. Successful businesses continually refine their methods, incorporating feedback and trends to achieve the best possible results.

Frequently Asked Questions

What are the recommended sizes for DTF transfers in custom printing?

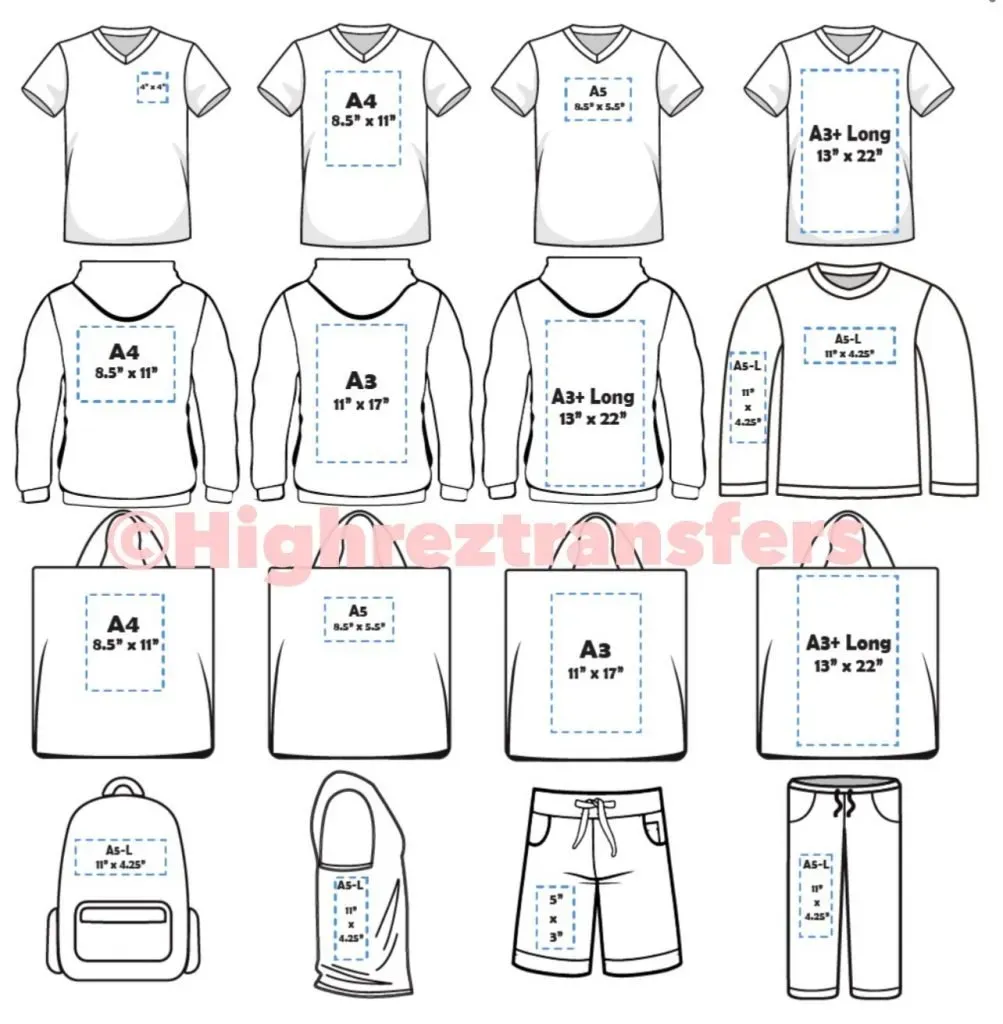

The recommended sizes for DTF transfers vary based on the type of garment and design intricacy. Typically, standard transfer sizes range from small (7×7 inches) for logos and graphics to larger sizes (up to 13×19 inches or more) for full apparel designs. Choosing the right size ensures optimal detail and visual appeal in your DTF printing.

How does transfer size impact the quality of DTF printing?

Transfer size significantly influences the quality of DTF printing. Larger transfers allow for greater detail and intricate designs, resulting in crisp and vibrant prints. Conversely, smaller transfers can sometimes lead to reduced detail, particularly for complex images. It’s crucial to balance size and quality to meet customer expectations in your custom printing projects.

Which garments work best with specific DTF transfer sizes?

Different garments require different DTF transfer sizes for optimal results. For example, small items like caps or bags typically use smaller transfers (about 4×4 inches), while t-shirts and hoodies work well with medium to large transfers (8×10 inches or larger). Understanding your garment types will tailor your custom printing to meet customer needs effectively.

What factors should be considered when selecting DTF transfer sizes?

When selecting DTF transfer sizes, you should consider factors like design complexity, garment type, and material compatibility. Larger sizes may require advanced printing capabilities for quality outputs, while smaller transfers are quicker to produce but may lack detail. Matching transfer size to customer preferences and fabric texture is key for successful apparel customization.

What trends are influencing DTF transfer sizes in the custom printing market?

Trends in the custom printing market indicate a growing demand for personalized apparel, encouraging the use of custom-sized DTF transfers. Consumers increasingly seek unique designs tailored to individual preferences, leading businesses to offer a variety of sizes to meet these demands. Keeping abreast of market trends is essential for capturing consumer interest in apparel customization.

How do future innovations in DTF technology affect transfer sizes?

Future innovations in DTF technology are set to enhance capabilities regarding transfer sizes. As printers become more advanced, businesses will have increased flexibility to create larger and more detailed transfers without sacrificing quality. Staying updated on these developments can help businesses adapt their offerings and thrive in the competitive custom printing landscape.

| Key Aspects | Explanation |

|---|---|

| Printer Capabilities and Transfer Sizes | The size of DTF transfers affects the quality and detail of prints; larger sizes necessitate advanced printing technology. |

| Customization Options | DTF technology allows for customized sizes for various products, catering to diverse client needs and preferences. |

| Material Compatibility | Transfer size influences the types of materials the transfers can effectively adhere to, impacting durability and design integrity. |

| Market Trends | As demand for personalized apparel grows, custom-sized transfers are becoming more popular, aligning with consumer desires for uniqueness. |

| Print Quality and Efficiency | Small sizes can be produced quickly but may lack detail, while larger sizes offer detail but require more production time. |

| Future Innovations | Technological advancements in DTF printing are providing more options for transfer sizes, allowing for greater flexibility and diversity in offerings. |

Summary

The size in DTF transfers is a critical factor that directly influences both the aesthetic quality and functional compatibility of printed designs. Understanding the importance of size can greatly enhance your customization capabilities, allowing you to meet diverse customer needs and maintain high-quality output. As the field of custom printing evolves with emerging market trends and consumer expectations for unique apparel, those who prioritize size considerations in DTF transfers are poised to thrive. By adapting your approach to sizing, you can improve operational efficiency and ensure your business remains competitive in the vibrant world of DTF printing.