UV DTF transfers are revolutionizing the printing landscape, offering a fresh alternative to traditional printing methods that have dominated the industry for years. This innovative technique utilizes advanced UV printing technology, allowing for high-resolution prints with vibrant colors and superb detail. In contrast to older printing processes, UV DTF significantly boosts printing efficiency and reduces production times, making it a game-changer for businesses. This article explores the print quality comparison between UV DTF and conventional methods, highlighting the distinct advantages and potential drawbacks. With a meticulous cost analysis of printing considerations, it’s clear that UV DTF transfers are paving the way for a more effective, durable, and cost-efficient future in printing.

Exploring the realm of Direct-to-Film (DTF) printing, particularly UV-based solutions, unveils the benefits of this modern approach to graphic reproduction. The UV-cured inks offer remarkable versatility, enabling prints that adhere firmly across a myriad of materials, from textiles to rigid surfaces. This processing method stands in stark contrast to legacy printing practices, which often face limitations in terms of speed and adaptability. A detailed evaluation of print quality highlights how UV DTF excels, providing visually stunning results that could easily outclass traditional alternatives. As industries shift towards more efficient and sustainable solutions, understanding the intricacies of UV DTF technology becomes increasingly vital for those looking to stay competitive.

Understanding UV DTF Transfers: A Modern Printing Solution

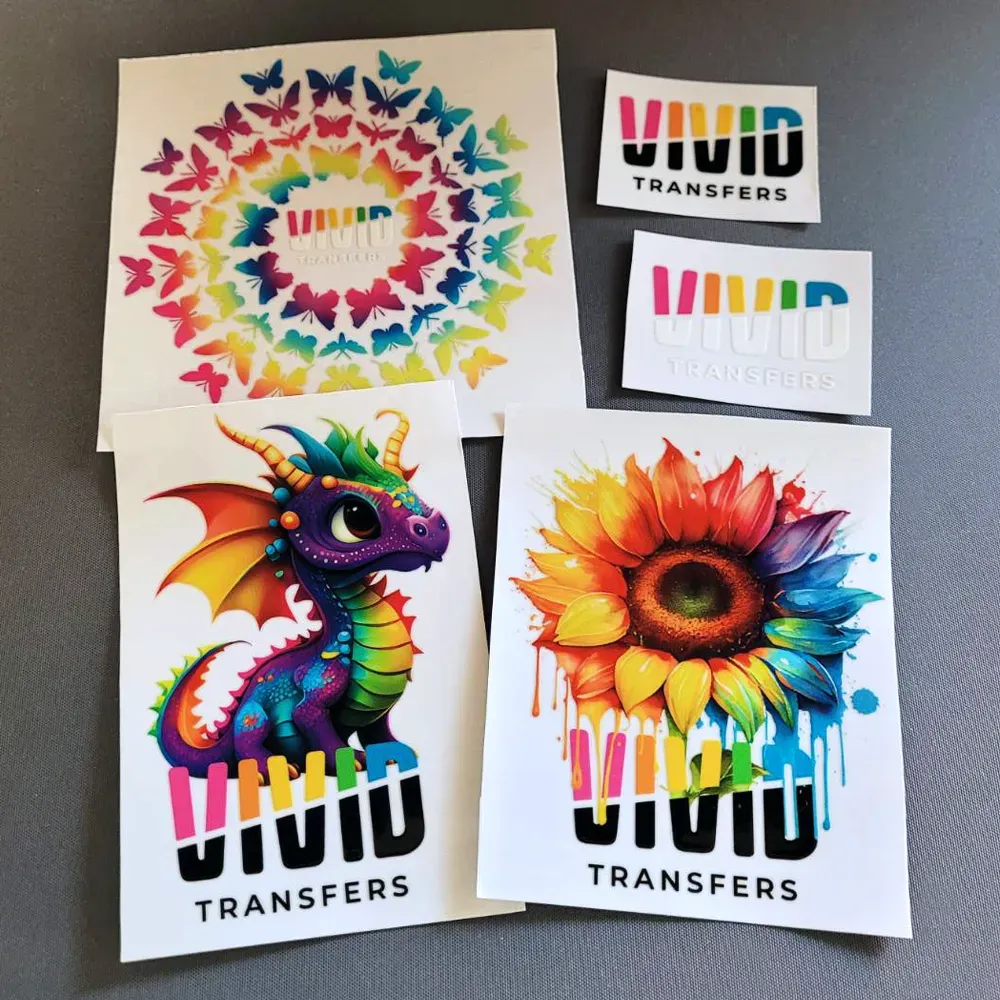

UV Direct-to-Film (DTF) transfers leverage UV-curable inks that dry instantly upon exposure to UV light, creating prints that stand out for their vibrancy and detail. This unique printing technology enables the production of intricate designs with a high level of clarity, which is essential in various industries, including fashion, merchandising, and promotional products. The process involves printing on a special film, which allows the user to transfer high-quality graphics to a wide array of surfaces including textiles, plastics, and metals.

In contrast to traditional printing methods such as screen printing or digital inkjet printing, UV DTF offers significant advancements in efficiency and quality control. The immediate curing of the inks not only revolutionizes the printing speed but also reduces errors commonly associated with wet inks, enhancing overall production efficiency. This adaptability makes UV DTF a desirable choice for businesses seeking innovative solutions in the competitive landscape of printing.

Frequently Asked Questions

What are the advantages of UV DTF Transfers over traditional printing methods?

UV DTF Transfers offer several advantages including superior print quality with vibrant colors and intricate details, faster production speeds due to instant curing, and compatibility with a wide variety of substrates. Unlike traditional printing methods that may struggle with detailed graphics and longer drying times, UV DTF technology enhances efficiency and versatility in printing.

How does print quality compare between UV DTF Transfers and traditional printing methods?

In terms of print quality, UV DTF Transfers clearly outperform traditional printing methods like screen printing. UV DTF produces high-resolution prints with a broad color gamut that capture fine details without blurring or smudging, which can be a challenge in traditional methods due to their layering processes.

What is the production speed of UV DTF Transfers compared to conventional printing?

UV DTF Transfers significantly improve production speed compared to conventional printing methods. The instant curing of UV inks allows for quicker turnaround times, with studies indicating productivity increases of up to 30% over traditional printing technologies, which often require lengthy drying and preparation times.

Are UV DTF Transfers suitable for various materials?

Yes, UV DTF Transfers are highly versatile and compatible with a wide range of substrates, including both rigid and flexible materials. This flexibility places UV DTF technology ahead of traditional printing methods, which may have stricter material requirements and limitations.

What is the cost analysis of UV DTF Transfers against traditional printing techniques?

While the initial investment in UV DTF technology may be higher, the cost-per-print is generally lower in the long run due to increased printing efficiency and reduced material waste. This makes UV DTF Transfers a cost-effective choice for businesses looking to balance upfront costs with long-term savings in printing.

What are the market trends for UV DTF Transfers in comparison to traditional printing methods?

The market for UV DTF Transfers is experiencing significant growth, projected at an annual rate of about 15%. This trend is driven by the increasing demand for fast and customizable printing solutions, positioning UV DTF as a preferred option in various commercial applications over traditional printing methods.

| Category | UV DTF Transfers | Traditional Printing Methods |

|---|---|---|

| Print Quality and Detail | High-resolution with vivid colors; less prone to smudging. | Can struggle with fine details and intricate designs. |

| Production Speed | Faster turnaround, with up to 30% productivity improvement. | Extended color preparations and drying times. |

| Material Versatility | Compatible with a wide range of substrates, rigid and flexible. | May require specific materials and treatments. |

| Durability and Longevity | Highly resistant to scratches, fading, and chemicals. | More vulnerable to the effects of the environment. |

| Cost Consideration | Higher upfront cost but lower long-term costs due to efficiency. | Lower upfront but potential for higher long-term costs. |

| Market Trends | Expected annual growth rate of about 15%. | Various market segments adapting at different rates. |

Summary

UV DTF Transfers present a transformative advancement in printing technology, offering remarkable benefits over traditional printing methods. The high resolution and vibrant color reproduction of UV DTF transfers ensure superior print quality, while their faster production speeds and extensive material compatibility enhance operational efficiency for businesses. Additionally, the longevity and durability of UV DTF prints make them a reliable choice for various applications. As the market continues to shift toward customized solutions, UV DTF Transfers are becoming increasingly essential for companies aiming to enhance their service offerings and maintain a competitive edge.