UV DTF transfers are revolutionizing the printing landscape with their unique combination of ultra-violet (UV) printing and Direct-to-Film techniques. This cutting-edge method enables businesses to create vibrant, high-quality prints that adhere beautifully to various surfaces, from textiles to hard materials like plastics and metals. As industries push for more versatile and durable printing solutions, understanding how to harness UV DTF technology can significantly boost your business potential. By implementing effective strategies and staying current with the latest printing techniques, you can tap into new opportunities within the competitive printing market. In the following sections, we’ll unlock valuable insights to help you maximize the advantages of UV DTF transfers.

When discussing innovative printing solutions, terms such as UV Direct-to-Film and DTF printing often emerge. These advanced printing methods are increasingly sought after by businesses aiming to produce custom designs with exceptional durability and detail. The integration of ultraviolet inks in the transfer process allows for unparalleled adaptability, making it possible to print on a wide range of materials. Furthermore, as consumer demand for personalized products continues to rise, exploring these sophisticated printing techniques can position your business at the forefront of industry advancements. Engaging with these technologies not only enhances your service offerings but also opens avenues for innovative marketing strategies.

The Advantages of UV DTF Transfers in Modern Printing

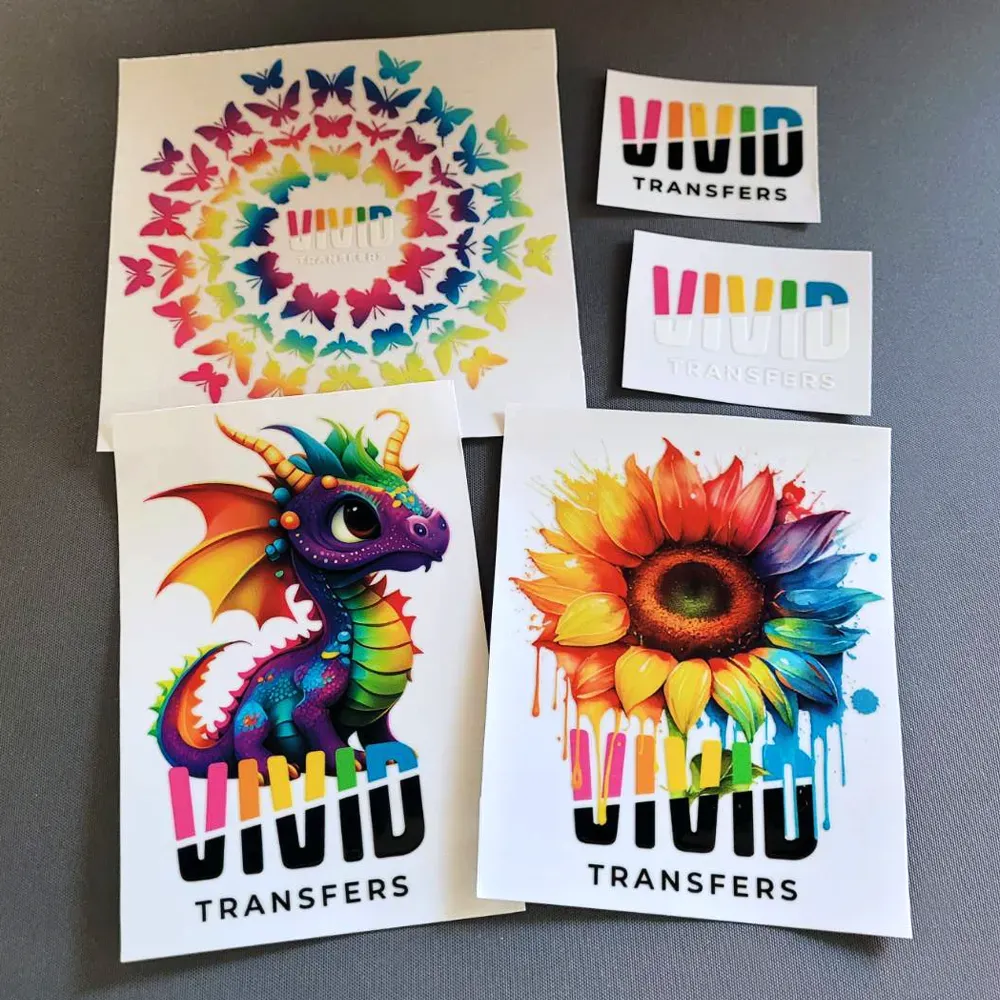

UV DTF transfers offer a multitude of advantages that make them an attractive choice for businesses in the printing industry. One of the primary benefits is their ability to produce stunning, high-resolution prints on various substrates. Unlike traditional printing methods, UV DTF utilizes ultraviolet light to cure inks instantly, which allows for more vibrant colors and intricate designs. This technology caters to the growing demand for customizable products, making it easier for businesses to meet customer expectations for quality and uniqueness.

Additionally, the durability of UV DTF prints is remarkable. These prints are resistant to fading, scratching, and wear, which is essential for products that will undergo regular handling or washing. This longevity not only enhances customer satisfaction but also reduces the need for reprints, ultimately saving businesses time and money.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers combine ultraviolent (UV) printing with direct-to-film techniques to produce vibrant and detailed prints. The process involves printing designs onto a film using UV inks, which can then be transferred onto various substrates, including textiles and hard materials like metals and plastics.

How does UV printing enhance the quality of DTF transfers?

UV printing enhances DTF transfers by utilizing UV inks that cure immediately upon exposure to UV light, resulting in sharp, high-resolution images. This method allows for durable, long-lasting prints that can withstand wear and tear, making it ideal for custom printing applications.

What substrates are suitable for UV DTF transfers?

UV DTF transfers can be applied to a variety of substrates, including fabrics, wood, glass, and metal. The versatility of this printing technique allows businesses to cater to diverse customer needs, expanding their service offerings in the custom printing market.

What are the advantages of using UV DTF transfers in a printing business?

The advantages of UV DTF transfers include high durability, vibrant colors, and the ability to print on multiple substrate types. These features not only enhance product appeal but also unlock significant business potential by allowing for a wider range of offerings and customization options.

How important is the curing process in UV DTF printing?

The curing process is critical in UV DTF printing as it solidifies the inks, ensuring print durability and washability. Proper curing with a reliable UV light source enhances the longevity of the prints, making it essential for successful custom printing operations.

What trends should businesses watch in UV DTF printing technology?

Businesses should stay informed on trends such as sustainability efforts, advancements in automation, and customer demands for customization. Keeping up with these trends in UV DTF printing technology can help businesses remain competitive and maximize their potential in the marketplace.

| Key Points | Description |

|---|---|

| Quality Equipment | Invest in high-quality UV DTF printers from reputable brands like Epson and Roland to enhance print quality and reduce maintenance. |

| Material Selection | Choose a variety of compatible substrates, such as fabrics, wood, and glass, to cater to diverse customer needs. |

| Inks and Adhesives | Utilize high-quality UV inks and adhesives designed for DTF transfers to ensure durability and strong adhesion. |

| Design Optimization | Create visually appealing designs using high-resolution images or vector graphics to maximize print quality. |

| Pre-Treatment Processes | Research necessary pre-treatment for specific substrates to enhance adhesion and reduce print failures. |

| Curing Process | Ensure proper curing with adequate UV light for print longevity and durability. |

| Stay Informed on Market Trends | Regularly update knowledge on industry trends and customer preferences to stay competitive. |

| Technological Advancements | Adopt automation and new technologies to improve efficiency and reduce manual labor. |

| Sustainability Initiatives | Incorporate eco-friendly inks and processes to attract eco-conscious customers and enhance brand value. |

Summary

UV DTF Transfers are revolutionizing the printing industry, enabling businesses to maximize their potential through high-quality, versatile printing technologies. This innovative method allows for the production of vibrant and durable prints on a variety of substrates, making it an excellent choice for custom apparel, promotional items, and more. To succeed in this competitive landscape, businesses must focus on quality equipment, strategic material selection, and the optimization of design processes. Adapting to technological advancements and market trends, while prioritizing sustainability, will be key to achieving long-term success with UV DTF transfers. By leveraging these strategies, entrepreneurs can not only enhance their offerings but also tap into a lucrative market segment, ensuring their businesses thrive.